-

Hetal V.

-

02-05-2025

-

0 comments

How Odoo Helps Businesses Avoid Stockouts and Overstocking?

Summary

Many businesses lose money due to stockouts and overstocking—two common inventory challenges. Stockouts (running out of items) result in lost sales and unhappy customers, while overstocking (excess inventory) ties up capital and increases storage costs. Both issues hurt cash flow and profitability.

Odoo ERP helps prevent stockouts and overstocking by tracking inventory in real time, forecasting demand, and automating replenishment.

Introduction

Running out of stock when customers are ready to buy? Or ending up with too much inventory collecting dust?

These issues cost businesses money, frustrate customers, and slow down growth. Stockouts lead to missed sales, while overstocking ties up cash and increases storage costs.

Managing inventory manually or with outdated tools only makes things worse. That’s where Odoo ERP comes in. With real-time tracking, demand forecasting, and automated replenishment, you can avoid stockouts with Odoo while eliminating excess inventory.

The result? Optimized stock levels, happier customers, and healthier cash flow.

Let’s Dive In…!

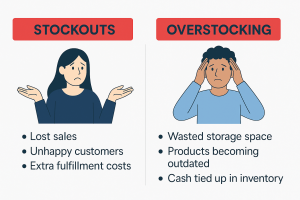

What Are Stockouts and Overstocking?

Stockout

Happens when you don’t have a product in stock. This leads to:

- Lost sales

- Unhappy customers

- Extra costs for fast delivery or finding replacement items

Overstocking

When you have too much of a product. This leads to:

- Wasted storage space

- Products going bad or becoming outdated

- Cash tied up in unsold items

Why Poor Inventory Management Hurts Your Business?

- Too much stock means higher storage and utility costs.

- Old stock may go to waste or need to be sold at lower prices.

- More items increase the chances of damage, theft, or mistakes.

- Running out of items disappoints customers.

- Poor inventory planning can hurt your cash flow and stop you from growing.

How Odoo Stock Management and Inventory Solutions Help Businesses?

Odoo ERP streamlines stock management and inventory control by offering powerful tools to:

- Track stock inventory in real time across warehouses.

- Predict demand accurately to avoid stockouts or overstocking.

- Automate purchase orders and restocking processes.

- Manage multiple warehouses within a unified system.

- Improve customer service with faster, more reliable deliveries.

- Monitor Odoo stock inventory costs and movements for better financial oversight.

With Odoo stock management, businesses reduce costs, optimize operations, and boost profitability.

Features of Odoo Inventory Module

Odoo inventory management helps you avoid running out of stock or having too much extra stock. It makes your supply chain faster and your logistics more organized. With smart tools like AI and real-time updates, Odoo stock management helps you plan better and work more smoothly.

1. Storage (Managing Your Stock)

- Multi-Warehouse Management: Manage multiple storage locations (e.g., Delhi warehouse, Mumbai store), and track stock separately for each location.

- Bin & Shelf Tracking: Organize products in specific shelves/bins (like “Aisle 3, Shelf B”), and find items quickly during picking.

- Batch/Expiry Tracking: Track products in batches (e.g., medicines, food). Get alerts before items expire.

- Serial Numbers: Assign unique IDs to expensive items (e.g., laptops, phones).

2. Operations (Daily Stock Activities)

- Barcode & QR Scanning: Scan items for fast receiving, picking, and delivery. No manual typing, fewer mistakes.

- Automated Reordering: Set minimum stock levels → Odoo suggests when to reorder, so you never run out of stock.

- Dropshipping: Sell products without keeping stock—supplier ships directly to customers.

- Internal Transfers: Move stock between warehouses/stores with a few clicks.

- Returns Management: Handle customer returns smoothly, Check condition before restocking.

- Quality Checks: Inspect products for damage/defects before selling.

- Reporting & Alerts: See stock levels, sales trends, and get low-stock warnings.

3. Advanced Routes (Smart Stock Movements)

- Push & Pull Rules: Set automatic stock movement rules (e.g., “Always keep 50 units in Showroom”).

- Cross-Docking: Ship goods directly from supplier to customer – no warehouse storage needed.

- Dropshipping Route: Automatically send customer orders to suppliers for direct delivery.

- Make to Order: Only produce/purchase items when customers order them.

- Make to Stock: Keep products ready based on predicted demand.

4. Productivity (Work Faster)

- Barcode Scanning: Scan items to update stock instantly – no typing needed.

- Mobile Inventory App: Manage stock from your phone or tablet anywhere.

- Batch Processing: Update multiple stock moves at once (save hours of work).

- Smart Pick Lists: Automatic packing lists show exactly what to prepare for orders.

- Low Stock Alerts: Get warning messages before you run out of products.

- Lightning Fast Search: Find any product in seconds using smart filters.

- Drag-and-Drop Interface: Move stock between locations with simple clicks.

5. Replenishment (Stay Stocked Up)

- Minimum Stock Levels: Set safety limits (e.g., “Reorder when only 10 left”).

- Auto Purchase Orders: System creates orders automatically when stock is low.

- Smart Forecasting: Predicts future needs using your sales history.

- Supplier Timing: Accounts for how long each supplier takes to deliver.

- Quick Reorder Templates: Save your frequent orders for 1-click reordering.

6. Traceability (Track Everything)

- Lot/Serial Numbers: Give unique IDs to track each item’s journey.

- Expiry Alerts: Get warnings before products expire (food/medicine).

- Complete History: See every movement – who did what and when.

- Recall Management: Quickly find and pull back faulty batches.

7. Products (Flexible Management)

- Multiple Units: Sell in boxes but track in pieces (e.g., 1 case = 24 bottles).

- Variants Made Easy: Handle sizes/colors as one product (e.g., T-shirt: S/M/L).

- Product Kits: Sell ready-made bundles (e.g., “Office Set” = pen+notebook+stapler).

- Digital Goods: Sell ebooks, software – no physical stock needed.

- Rental Items: Track what’s available for rent (tools, equipment).

- Smart Categories: Organize products in logical groups.

8. Inventory Valuation (Know Your Worth)

- Live Value Tracking: Always see the current total value of your stock.

- Flexible Cost Methods: Choose FIFO, Average Cost or Standard pricing.

- Auto Accounting Sync: Stock values update in your accounting automatically.

- Valuation Reports: See how your inventory value changes over time.

9. Reporting (Smart Insights)

- Stock Snapshots: See what you have now and predict future stock.

- Turnover Rates: Know which products sell fast/slow.

- Movement Tracking: Monitor which items are most/least active.

10. Integrations (Everything Connects)

- Sales Sync: Stock updates instantly when sales happen.

- Accounting Link: Inventory values flow to your financial reports.

- Online Store: Show live stock levels on your website.

- Manufacturing: Track materials and finished goods together.

- POS System: Real-time updates for retail stores.

- Purchasing: Auto-create orders when supplies run low.

How to Avoid Stockouts and Overstockings with Odoo?

1. Implement Demand Forecasting

- Demand forecasting enables you to order the right amount of inventory to meet the year-long demand and minimize inventory cost. It lets you avoid stockouts and overstocking in inventory.

- With predictive data analysis, you can better manage decisions on previous months’/years’ sales orders, enabling you to determine the right inventory size.

2. Consider Just-in-time Management:

- Just-in-time inventory management enables you to maintain the stock level in your warehouse as supplies are ordered only when required.

- This Odoo stock management feature significantly reduces inventory cost and keeps your warehouse’s stock levels low. This eliminates the need to maintain safety stock and reduces stockouts and overstocking.

3. Set reordering rules

- Setting reordering rules will automatically trigger procurement when stock levels fall below a certain threshold. Use this Odoo stock automation feature to set a minimum and maximum quantity to ensure timely replenishment and avoid stockouts with Odoo.

- The Replenishment Page offers a centralized view for managing and tracking reordering processes, enhancing overall supply chain efficiency.

4. Enable Inventory Routes and Procurement Rules:

- Configuring inventory routes and procurement rules based on product and warehouse, depending on business logic, reduces stockouts and excess.

5. Use Safety Stock Levels

- Another way to avoid stockouts with Odoo is to implement safety stocks. It prevents stockouts due to unexpected demand or delays in supply.

- You can configure safety stock levels in reordering rules. For instance, if the average demand is 30/week, you can keep 35 as a buffer in case of unexpected orders.

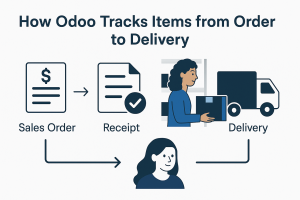

6. Track Stock in Real-Time

- By tracking real-time inventory in Odoo, you will know your current stock levels, pending receipts, and deliveries.

This helps you make informed decisions quickly, reducing errors and preventing stockouts and overstocking.

In a case study of Vinos Cruzados, a boutique wine retailer, the company was unable to expand its operations into the e-commerce space as it was using different systems for sales, inventory, and web management.

Odoo’s inventory, sales, and e-commerce modules were thus implemented for an all-in-one solution. They built a powerful online store and integrated the inventory system to gain real-time stock updates across their sales channels.

As a result, they saw a 35% boost in sales within the initial six months. Integrating their physical and online store inventories gave them accurate stock levels. They were able to prevent overstocking in warehouse, boosting customer satisfaction.

7. Use Lead Time Management

- Setting vendor lead times and manufacturing lead times accurately in Odoo has a positive impact.

This Odoo stock automation feature ensures that you order goods in advance to arrive when needed.

- It prevents delays and helps avoid stockouts with Odoo caused by slow suppliers.

8. Regular Inventory Audits and Adjustments

- Physical inventory checks help correct mismatches between system data and actual stock.

- Odoo supports cycle counts and inventory adjustments to ensure stock records are accurate. It reduces stockouts and overstocking due to incorrect data.

Conclusion

Odoo empowers businesses with the right tools to strike the right balance between supply and demand. You can avoid stockouts with Odoo and prevent your warehouse from overstocking through accurate forecasting, real-time inventory tracking, and automated restocking.

Ready to take control of your inventory? Try Odoo’s smart stock management features today.

At Icon TechSoft, a leading Odoo development company, we specialize in end-to-end Odoo ERP implementation, integration, and support. With 10+ years of experience in successful Odoo deployments, we help businesses gain real-time visibility and precise control over inventory.

Partner with us to:

- Reduce human errors and improve stock accuracy.

- Optimize inventory levels to meet demand without overstocking.

- Cut costs with automated replenishment and data-driven decisions.

Let us help reduce human errors, improve stock accuracy, and ensure that your business maintains the right inventory levels to meet customer demands while minimizing costs.

![]()

![]()

![]()